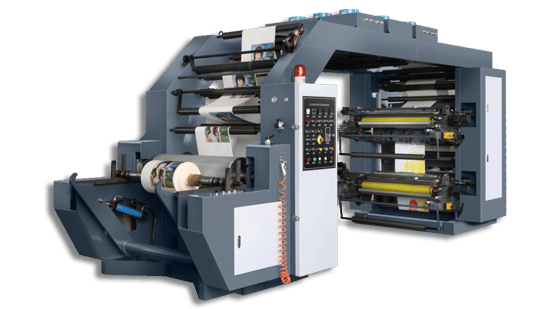

Flexographic printing machine is another versatile product. Over time, packaging labels have become an essential material for advertising because it builds a connection between the business and its consumers. The machine employs relief plates made of photopolymer plates and flexible rubber.

Flexographic printing can be seen as a commercial printing style, which is used by reputed companies which need high volumes of labels and packaging. The manufacturers suggest these machines for their ability to print on almost any substrate, with a variety of inks to produce high-quality prints. The printing process takes four rollers like ink roller, plate cylinder, meter roller, and impression cylinder.

Flexographic printing can be seen as a commercial printing style, which is used by companies that require high volumes of labels as well as packaging. Reputed flexographic printing machine manufacturers recommend these machines for their ability to print on almost any substrate, with a variety of inks to produce high-quality prints. The printing process consists of four rollers like ink roller, plate cylinder, meter roller, and impression cylinder.

Let’s talk about the host of advantages it offers:

Automated

Once printing is set up, the automation process starts. The printing material is fed into the machine from a roller, which crosses every plate used systematically. The plates then roll the ink onto the material. Automation is the best advantage over the rest of the printing styles available in the market.

Cost-Efficient

Being mostly automated, flexographic printing machines hardly relies on any manual labor. This adds to its cost-effectiveness because the ink used in printing is also cheaper as compared to other printing methods. Since the orders are accomplished in large quantities, it ends up saving a significant amount of money.

Speed

A flexographic printing machine uses most of the space available before the printing information gets cut in an accurate shape. The leading Flexographic printing machine manufacturers indicate that a machine can print up to 750 meters per minute. With a quick turnaround time, the machines are highly useful.

Versatile

The machines come with versatility as there is no one right way to print using the machine. It can print using plates with materials that are fed from rolls and cut into an accurate size. With no waste of space or materials, it is appreciated for printing in record times.

| Max. Printing material width | 1220 mm |

| Printing length range | 300-1000mm |

| Max .Mechanical Printing speed | 120 m/ min. |

| Register precision | ≤±0.15mm |

| Thickness of plate | 1.7mm |

Ronald International is a leading manufacturer of flexographic printing machines in India. With our extensive technical staff, we can upgrade our flexo printing machine with innovative designs to meet the exact needs of our customers, and that too, at the best operational cost.

Ronald Web Offset the company of International repute is a privately held family owned company engaged in manufacturing ‘RONALD’ line of presses Since 1983.

Copyright © 2022 Ronald Web Offset All Rights Reserved